Biomass Boiler

Biomass Boiler

The heart of any biomass generation system lies in its boiler, which generates the heat required to drive the generator that produces electricity. A well designed and maintained boiler is efficient, clean and will run for decades.

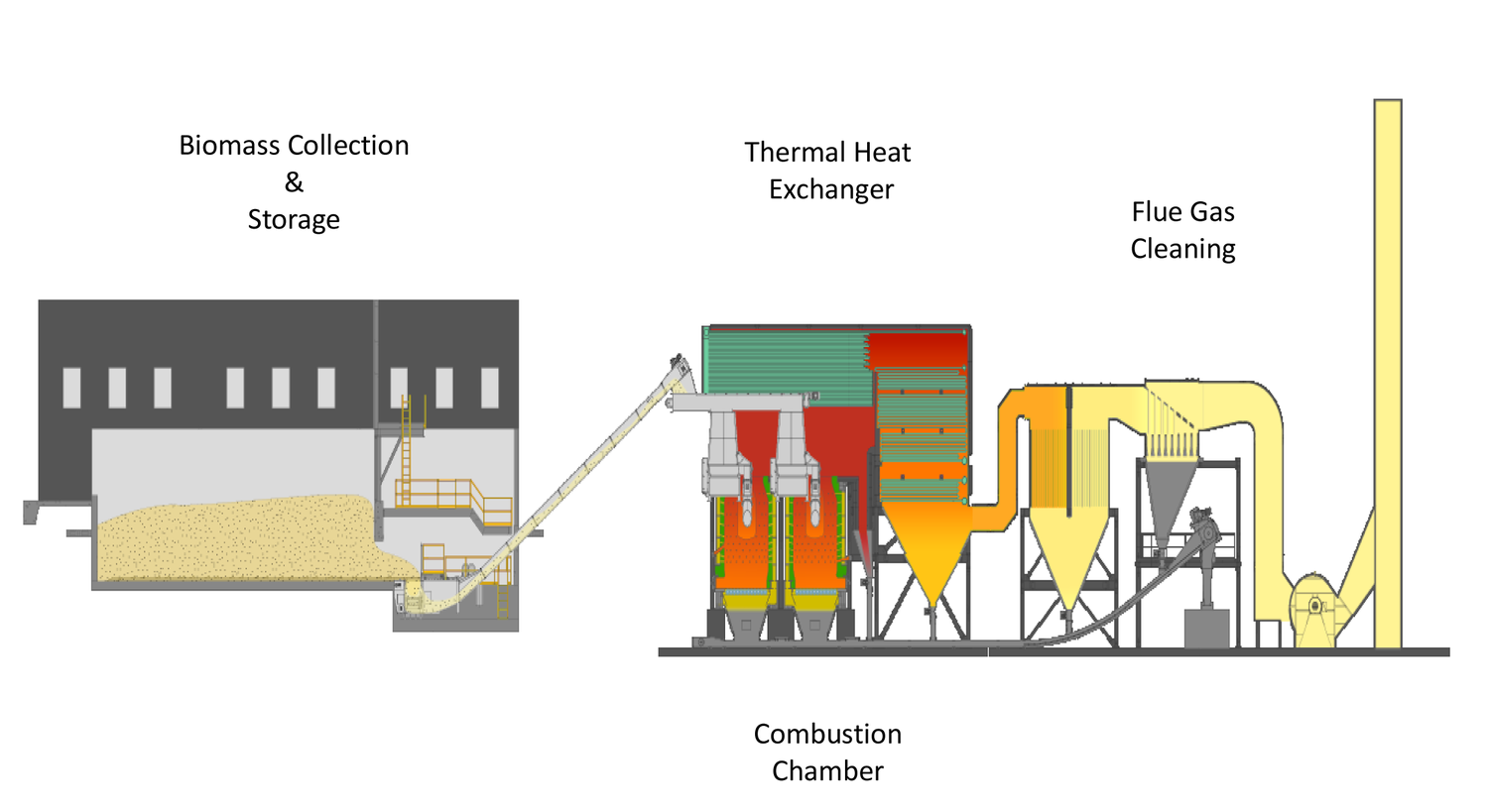

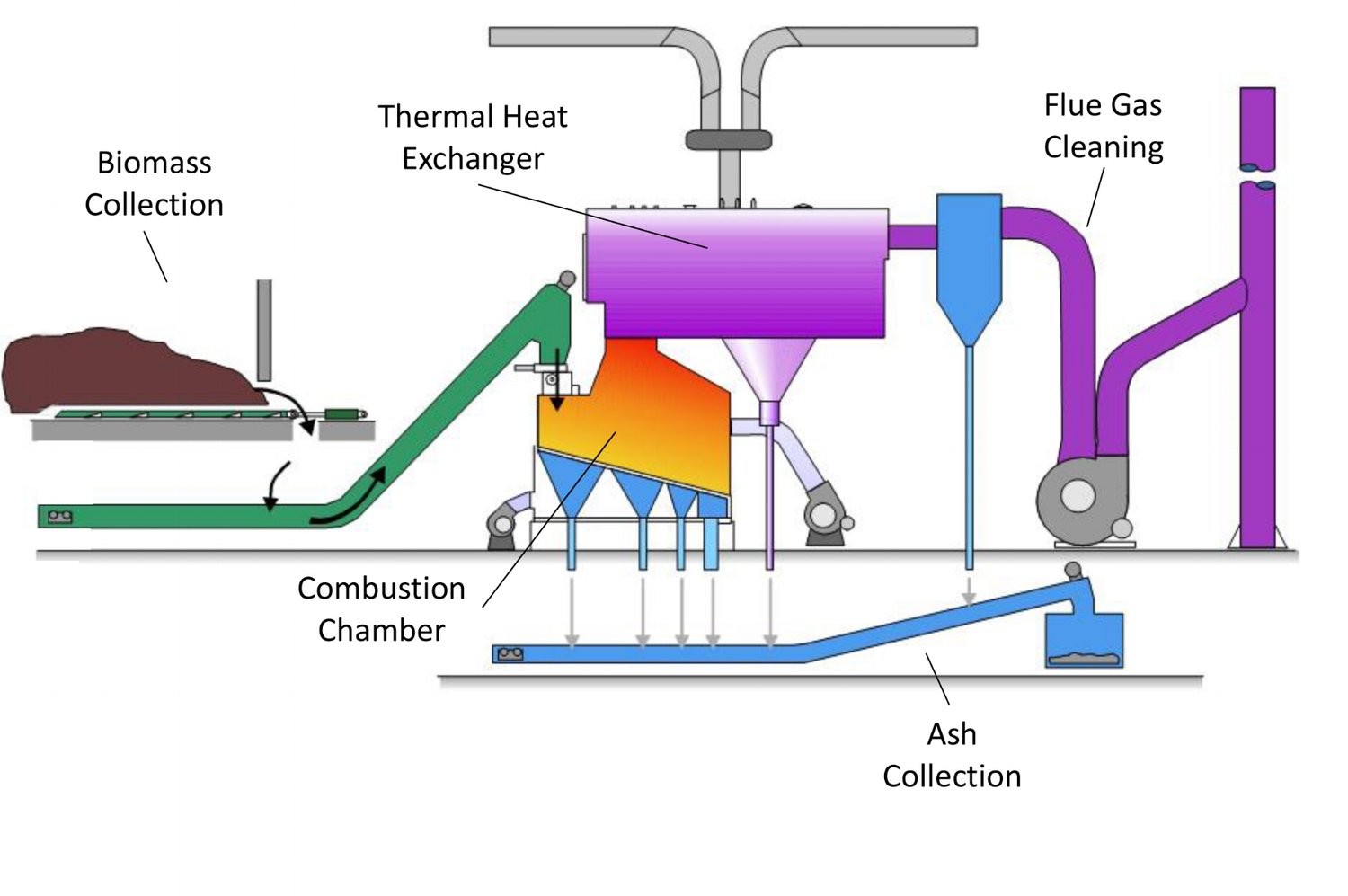

A boiler configured for biomass electricity generation is typically enclosed in a building to permit ease of access under all weather conditions. When operating, biomass is combusted in a large, brick lined furnace chamber with a heat exchanger on top that captures heat. Hot exhaust gas flows upwards from the furnace chamber into the heat exchanger where an enclosed pipe containing inert oil heats up to 310° C, ultimately cycling to an ORC turbine and the generation unit.

Today’s boilers are very efficient with very complete combustion of biomass fuel so that only fully combusted ash remains. The ash that is produced from burned wood chip fuel, wills fall to the bottom of the boiler and be automatically removed by a power auger. Once removed, it is stored and spread on the forest floor, where it augments the soil’s health and nutrient content.

Exhaust flue gases are treated with state of the art multi-cyclone equipment removing any undesired large particulate matter and are designed and monitored to ensure careful compliance with acceptable emission standards.

Please see below for two types of commonly used boiler configurations: